Last Updated: April 22, 2025

Discover how AI-driven 3D printing is revolutionizing manufacturing in 2025 with intelligent design optimization, real-time quality control, and breakthrough materials.

The Perfect Marriage: AI and 3D Printing

Remember when 3D printing was just for hobbyists making little plastic trinkets? Those days are long gone. In 2025, we’re witnessing something truly incredible—the fusion of artificial intelligence with 3D printing technology is completely transforming how we design, create, and manufacture products across every industry imaginable.

I’ve spent years watching this technology evolve, and honestly, I’ve never seen innovation move this quickly. What started as a way to make simple prototypes has evolved into an AI-powered manufacturing revolution that’s reshaping everything from healthcare to aerospace.

The most exciting part? We’re just scratching the surface of what’s possible.

How AI is Supercharging 3D Printing in 2025

The marriage between AI and 3D printing isn’t just improving existing processes—it’s creating entirely new possibilities that were unimaginable just a few years ago. Let me walk you through the most significant developments happening right now:

1. Intelligent Design Optimization

Gone are the days of painstakingly designing every aspect of a 3D model manually. Today’s AI algorithms can now analyze functional requirements and automatically generate optimized designs that would take human designers weeks or months to develop.

For example, when BMW Group needed to optimize their industrial planning processes, they turned to AI solution SORDI.ai. This system scans physical assets and creates digital twins that run thousands of simulations to optimize production efficiency. The result? Components that are lighter, stronger, and use significantly less material than their traditionally designed counterparts.

What makes this truly remarkable is how AI can think beyond human design patterns. The algorithms explore solutions humans might never consider, resulting in organic, almost alien-looking structures that outperform conventional designs in every metric.

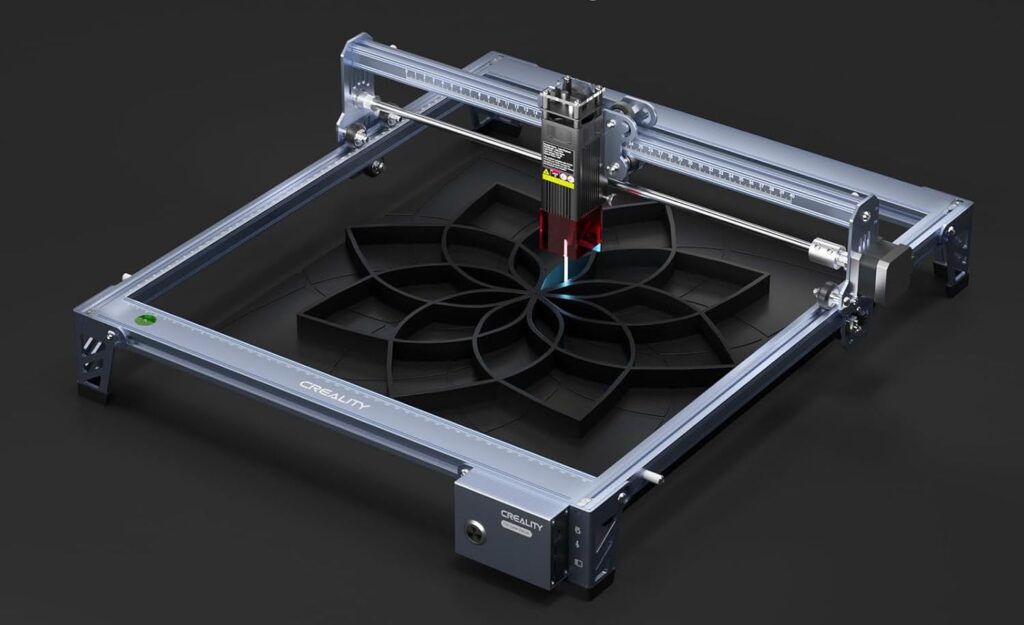

2. Real-Time Print Monitoring and Quality Control

One of the biggest headaches with traditional 3D printing has always been print failures. There’s nothing worse than coming back to your printer after hours of printing only to find a tangled mess of plastic spaghetti.

AI has virtually eliminated this problem through sophisticated computer vision systems that monitor prints in real-time. These systems can:

- Detect microscopic anomalies invisible to the human eye

- Automatically adjust printing parameters on-the-fly to compensate for irregularities

- Predict potential failures before they happen and take corrective action

- Continuously learn from each print to improve future results

This isn’t just saving materials and time—it’s enabling the production of critical components for industries where failure isn’t an option, like aerospace and medical implants.

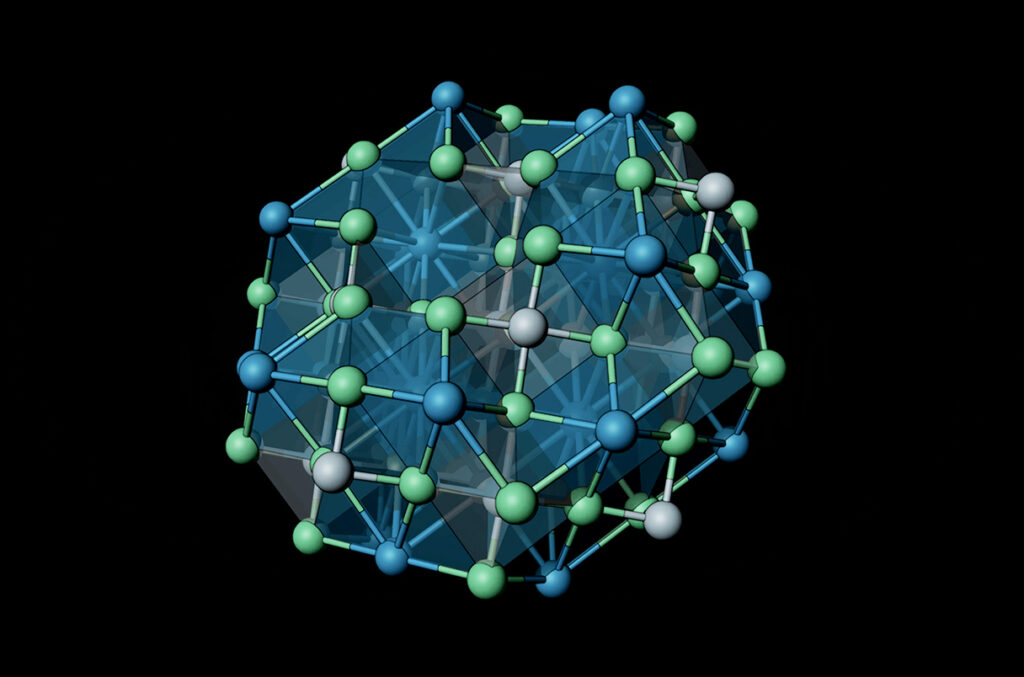

3. Material Innovation Through AI Prediction

Creating new materials for 3D printing used to be a slow, expensive process of trial and error. Today, AI algorithms can simulate and predict how different material compositions will perform, dramatically accelerating development.

In 2025, we’re seeing an explosion of new printing materials thanks to AI, including:

- Ultra-strong yet lightweight polymer composites for aerospace

- Biocompatible materials for medical implants

- Conductive materials that can print electronic circuits directly

- Sustainable materials made from recycled or renewable sources

These AI-developed materials aren’t just incremental improvements—they’re opening entirely new applications that weren’t possible before.

Real-World Applications Transforming Industries

The impact of AI-driven 3D printing is being felt across virtually every sector. Here are some of the most impressive real-world applications I’ve seen:

Healthcare Transformation

The healthcare industry has embraced AI-driven 3D printing with remarkable results. In early 2025, Organovo made headlines with their bioprinting technology that creates prosthetics perfectly matched to individual patients’ anatomy.

Even more impressive is the use of machine learning to optimize the creation of patient-specific surgical models. Surgeons can now practice complex procedures on perfect replicas of a patient’s anatomy before ever entering the operating room. This approach has led to shorter surgeries, faster recovery times, and better patient outcomes.

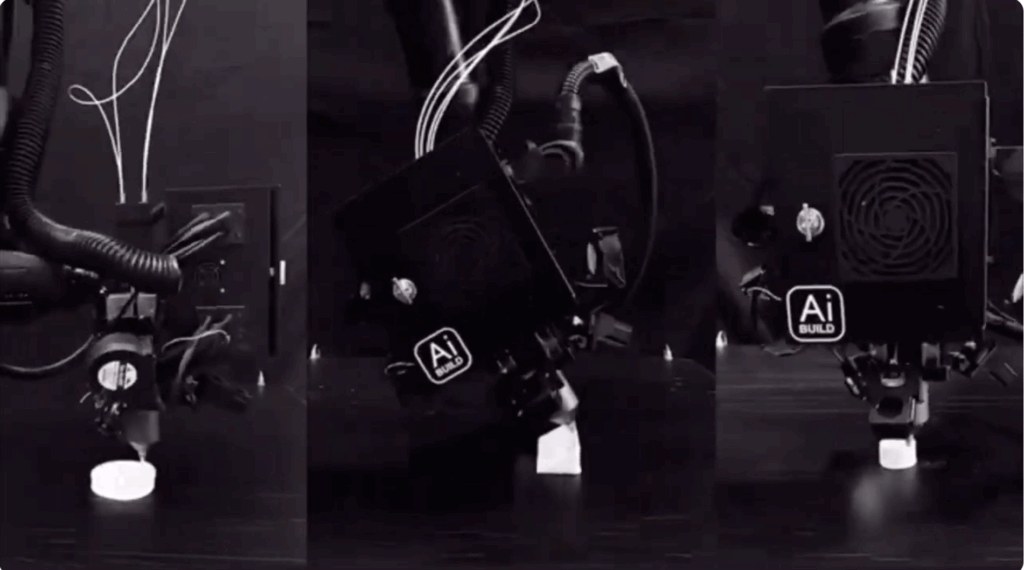

Manufacturing Reinvented

Traditional manufacturing involves massive upfront costs for tooling and setup, making small production runs prohibitively expensive. AI-powered 3D printing has flipped this equation on its head.

Today’s smart manufacturing systems can:

- Automatically optimize production schedules across distributed printer networks

- Predict maintenance needs before equipment fails

- Seamlessly switch between producing different products without retooling

- Generate optimized support structures that minimize material waste

The result is a democratization of manufacturing—suddenly, small businesses can compete with industry giants by producing small batches of highly customized products at competitive prices.

Aerospace & Automotive Advancements

The aerospace and automotive industries have perhaps the most to gain from AI-driven 3D printing. Components that previously required assembly from dozens of parts can now be printed as single, integrated structures.

In early 2025, a major aerospace manufacturer revealed they had reduced the weight of a critical engine component by 35% while simultaneously improving durability by 28%—all thanks to AI-designed and 3D-printed parts.

The Technology Behind the Revolution

So what exactly makes AI-driven 3D printing so powerful? It’s the convergence of several cutting-edge technologies:

Deep Learning for Design Optimization

The latest deep learning algorithms can analyze thousands of design iterations, learning from each to continuously improve results. These systems understand the relationship between design parameters and performance outcomes, allowing them to create counterintuitive but highly effective designs human engineers might never consider.

Computer Vision for Quality Control

Sophisticated computer vision systems powered by convolutional neural networks can analyze printer operation in real-time. By comparing what’s happening against expected results, these systems can detect even subtle anomalies and either make corrections or alert operators.

Reinforcement Learning for Process Optimization

Reinforcement learning algorithms continuously experiment with printing parameters, learning from each success and failure to optimize the process. Over time, these systems develop sophisticated printing strategies that maximize quality while minimizing time and material usage.

Challenges Still to Overcome

Despite the incredible progress, AI-driven 3D printing still faces some significant challenges:

Regulatory Hurdles

For critical applications like medical implants or aerospace components, regulatory approval remains a major hurdle. The unusual, AI-generated designs often don’t fit neatly into existing certification frameworks, requiring new approaches to validation and testing.

Computation Requirements

The computational demands of AI-driven design and real-time monitoring are substantial. Many smaller manufacturers struggle to afford the necessary computing infrastructure, though cloud-based solutions are helping to address this issue.

Material Limitations

While AI is accelerating material development, we’re still limited by the fundamental properties of available materials. Many applications remain challenging due to temperature limitations, strength requirements, or the need for specific electrical or thermal properties.

The Future: What’s Coming Next

Looking ahead, I see several exciting developments on the horizon for AI-driven 3D printing:

Multi-Material Intelligence

Current systems predominantly work with single materials or simple combinations. The next frontier is AI that can intelligently design with multiple materials simultaneously, creating objects with precisely engineered properties throughout their structure.

Closed-Loop Manufacturing

We’re moving toward completely autonomous manufacturing systems where AI designs products, optimizes production, monitors quality, and continuously improves—all with minimal human intervention.

Distributed Manufacturing Networks

AI will increasingly coordinate networks of printers distributed globally, enabling production close to the point of use while maintaining consistent quality and optimizing for local conditions and materials.

Conclusion: The Beginning of a New Era

We stand at the beginning of a profound transformation in how humanity designs and creates physical objects. AI-driven 3D printing isn’t just an incremental improvement to existing manufacturing—it’s a fundamental reimagining of what’s possible.

The combination of artificial intelligence and additive manufacturing is allowing us to create objects that are lighter, stronger, more efficient, and more sustainable than anything possible through traditional methods. From life-saving medical devices to next-generation aerospace components, the impact is already being felt across industries.

For businesses looking to stay competitive, investing in this technology isn’t just an option—it’s increasingly becoming a necessity. Those who embrace the power of AI-driven 3D printing will find themselves with capabilities their competitors can only dream of.

The question isn’t whether AI will transform 3D printing—that’s already happening. The real question is how quickly you’ll adapt to this new reality.

About the author: This article was written by someone who’s spent over a decade watching the 3D printing industry evolve from curiosity to revolutionary technology. While I do earn commissions when you purchase through some links on this site, I only recommend solutions I truly believe will help your business succeed in this exciting new landscape.