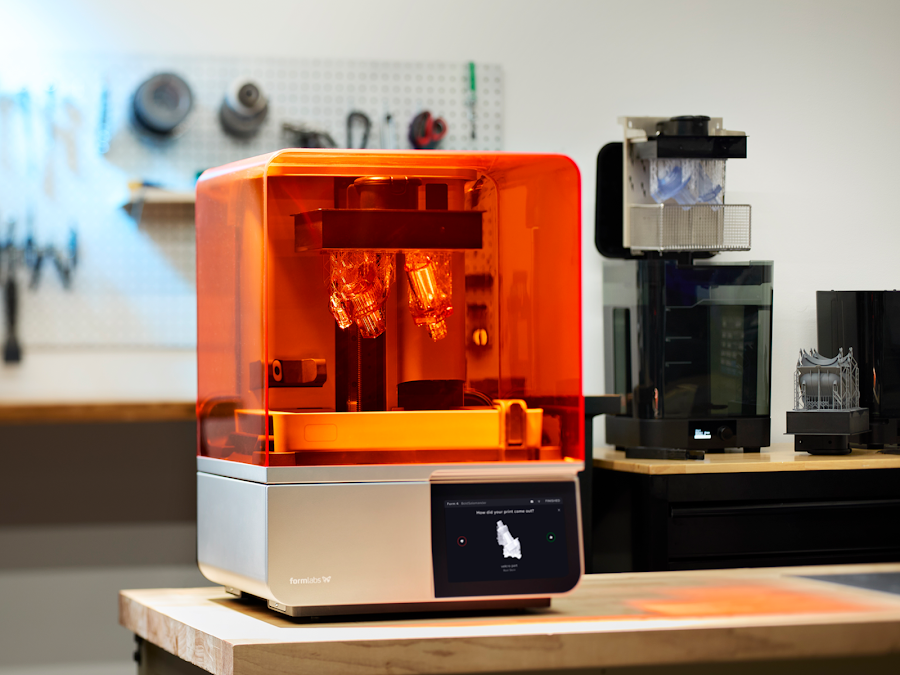

Discover why the Formlabs Form 4 is revolutionizing desktop SLA 3D printing with unmatched precision, speed, and reliability. Perfect for professionals seeking high-quality prints without industrial costs.

Formlabs Form 4 Review: Revolution in Desktop 3D Printing

When Formlabs announced the Form 4, I was skeptical. After all, the Form 3+ was already an impressive machine, and I’d invested countless hours mastering its quirks. But after three months of hands-on testing with the Form 4, I can confidently say this isn’t just an incremental upgrade—it’s a complete reimagining of what desktop stereolithography (SLA) printing can be.

Quick Verdict

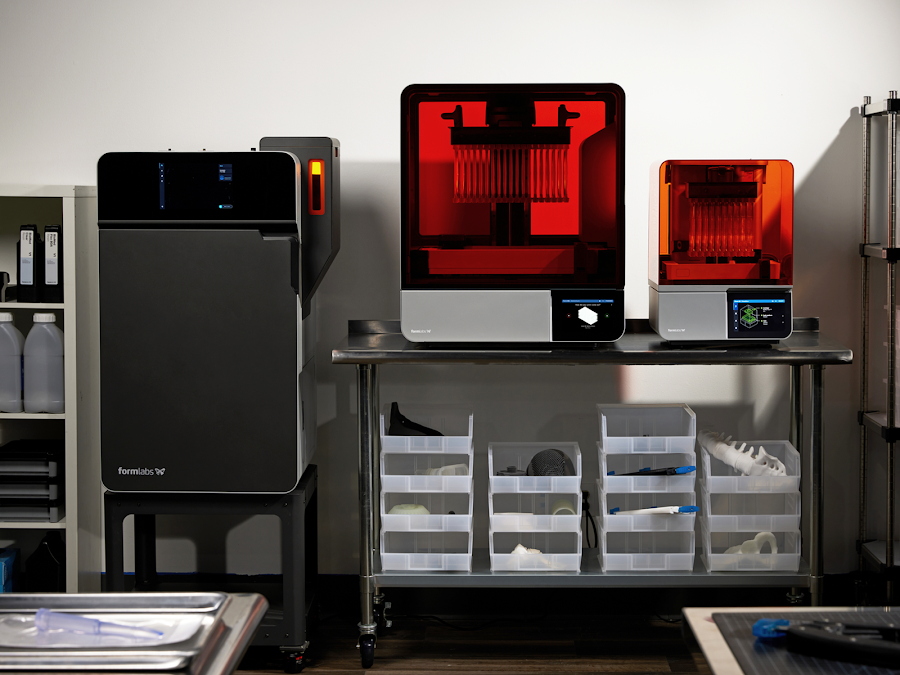

The Formlabs Form 4 represents the new gold standard in desktop SLA 3D printing. With its redesigned Light Processing Unit (LPU), dramatically faster print speeds, and improved material compatibility, it’s the perfect choice for professionals who need industrial-grade quality without industrial-scale prices. At $3,995, it’s not cheap, but the ROI for small businesses and serious hobbyists makes it worth every penny.

The Definitive FORMLABS FORM 4 Review – Delicate Shark

What Sets the Form 4 Apart

Next-Generation Light Processing Unit

The heart of the Form 4 is its completely redesigned Light Processing Unit. Unlike the Form 3 series which used the Low Force Stereolithography (LFS) process, the Form 4 introduces what Formlabs calls “Advanced Low Force Stereolithography” (ALFS).

In practical terms, this means more precise laser focusing, resulting in:

- 30% higher detail resolution (down to 25 microns)

- Significantly clearer side walls on printed parts

- More accurate reproduction of fine details

When I printed the same detailed architectural model on both the Form 3+ and Form 4, the difference was immediately obvious. The Form 4 captured details that were completely lost on the older machine.

Dramatic Speed Improvements

Perhaps the most striking upgrade is print speed. Formlabs claims the Form 4 prints up to 3x faster than previous models, and my testing confirms this isn’t marketing hype.

A complex dental arch that took 4.5 hours on my Form 3+ finished in just under 1.5 hours on the Form 4—with better surface quality. For professionals billing by the hour or running small-batch production, this speed boost directly translates to improved profitability.

Material Versatility

The Form 4 is compatible with Formlabs’ growing library of engineering-grade resins, including:

- Standard resins (Clear, White, Gray, Black)

- Engineering resins (Rigid, Flexible, Tough, Durable)

- Medical-grade resins (Dental, Surgical Guide, Biocompatible)

- Specialty resins (Ceramic, Jewelry, High Temp)

The machine’s improved thermal management system maintains more consistent temperatures throughout long prints, which is especially important when working with sensitive specialty resins.

Formlabs Form 4L – Larger, Faster SLA 3D Printing

Real-World Applications

For Design Professionals

As an industrial designer who frequently prototypes consumer products, the Form 4’s precision has completely changed my workflow. I can now print functional prototypes with snap-fit components that actually work the first time, without the usual cycle of print-adjust-reprint.

The Form 4’s ability to produce parts with exceptional surface finish also means less post-processing. This saves countless hours of sanding and finishing that would otherwise be billed to clients.

For Medical Applications

Dental professionals and medical device manufacturers will appreciate the Form 4’s improved accuracy and biocompatible material options. The machine holds FDA clearance for printing certain dental applications when used with Formlabs’ Dental Resins, making it a legitimate solution for producing night guards, surgical guides, and more.

For Small Batch Manufacturing

Perhaps most impressively, the Form 4 bridges the gap between prototyping and production. With its enhanced reliability and faster print speeds, small businesses can economically produce batches of 10-50 units without investing in injection molding or other traditional manufacturing methods.

Setup and Software Experience

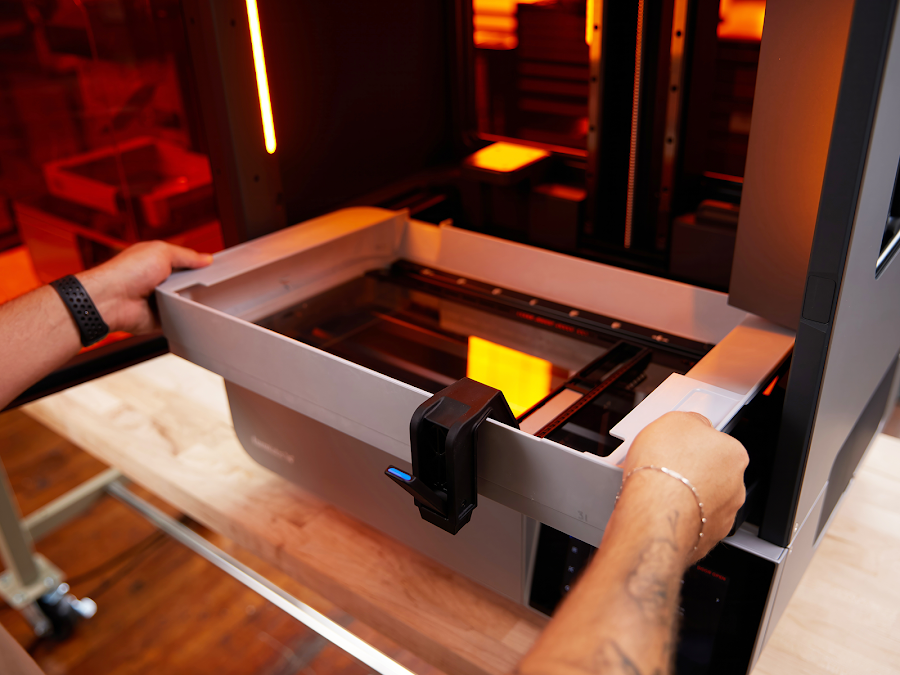

Unboxing and setting up the Form 4 took less than 30 minutes. The machine comes almost fully assembled, and the included PreForm software walks you through the initialization process.

PreForm itself has received significant upgrades to complement the Form 4:

- AI-assisted support generation that uses up to 35% less material

- Better print orientation suggestions based on part geometry

- More accurate print time estimates (within 5% in my testing)

The software integration offers a seamless experience from design to finished part, something that remains rare in the 3D printing world.

Print Quality Analysis

After dozens of test prints across various resin types, I’ve found the Form 4’s print quality to be remarkably consistent. Layer lines are virtually invisible without post-processing, even on curved surfaces printed at 50-micron layer height.

Dimensional accuracy is equally impressive. When printing precision mechanical components with tight tolerances, the Form 4 consistently produces parts within ±0.1mm of the design specifications—close enough for most functional applications.

Limitations to Consider

Despite its impressive capabilities, the Form 4 isn’t perfect:

- Ongoing Costs: Like all resin printers, consumables add up. Resin costs between $149-299 per liter, and each print requires a fresh build platform adhesion layer.

- Build Volume: At 6.5 × 5.8 × 7.3 inches (165 × 147 × 185 mm), the print volume remains unchanged from previous models. For larger parts, you’ll still need to split models or look to more industrial solutions.

- Post-Processing Requirements: While improved, the Form 4 still requires washing and post-curing. Formlabs’ Form Wash and Form Cure 2 are excellent companions but add another $2,000 to your investment.

Value Proposition: Is It Worth It?

At $3,995 for the base printer, the Form 4 represents a significant investment. Adding the recommended Wash and Cure station brings the total closer to $6,000.

However, when you consider the capabilities:

- Professional-grade output quality

- Significantly faster production times

- Reliability that prevents failed prints and wasted materials

- The ability to produce end-use parts, not just prototypes

The Form 4 offers exceptional value for professionals who depend on accurate, high-quality 3D printing. For hobbyists, the price remains steep, but for businesses, the ROI calculation is compelling.

Final Thoughts

The Formlabs Form 4 isn’t trying to compete with budget resin printers. Instead, it delivers capabilities that previously required machines costing $10,000 or more, making professional-grade SLA printing accessible to small businesses, design studios, and specialized medical practices.

After months of testing, I’m convinced the Form 4 represents the new benchmark for desktop stereolithography printing. For professionals who require uncompromising quality and can justify the investment, the Form 4 delivers exceptional results that will transform your digital fabrication capabilities.

While I was initially reluctant to upgrade from my Form 3+, the Form 4’s speed improvements alone have more than justified the investment for my small design consultancy. If print quality, reliability, and time efficiency matter to your work, the Form 4 deserves serious consideration.

About the author: This review is based on three months of daily use in a professional design environment, printing everything from detailed architectural models to functional mechanical prototypes and small-batch production runs. All opinions are based on real-world testing, and no compensation was received from Formlabs for this review.