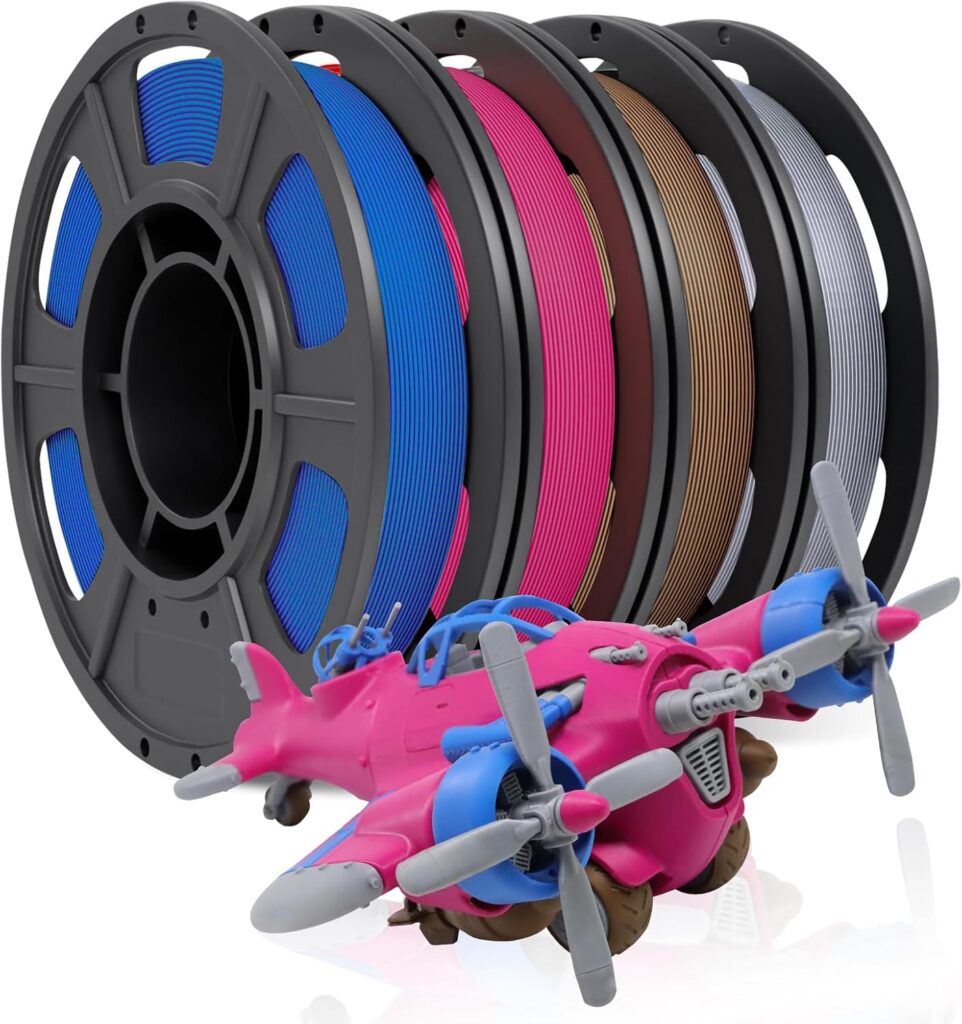

Choosing the right filament is crucial for achieving the best results in your 3D printing projects. With a plethora of options available on Amazon, it can be overwhelming to select the perfect material. Let’s explore some top-rated filaments that have garnered high praise from the 3D printing community.

Understanding 3D Printer Filament Types

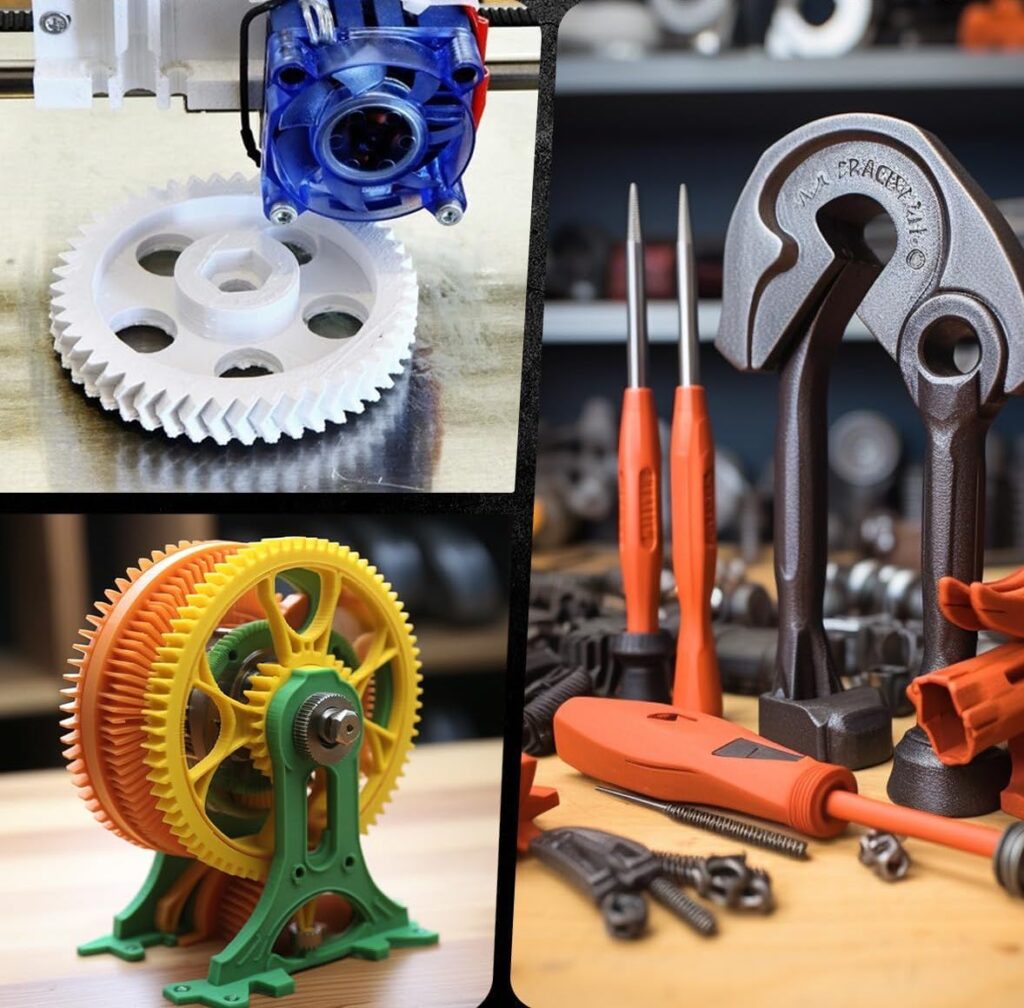

Before diving into product recommendations, it’s important to understand the different types of filaments available. Each material offers unique properties that cater to various applications. Below are some of the most commonly used filaments:

PLA is one of the most popular and beginner-friendly 3D printing materials. It is derived from renewable resources like cornstarch and sugarcane, making it environmentally friendly. PLA is easy to print with, has minimal warping, and is suitable for a wide range of applications, including prototypes, decorative pieces, and household items.

Pros:

- Easy to print

- Environmentally friendly

- Wide variety of colors and finishes

Cons:

- Brittle compared to other filaments

- Not ideal for high-temperature applications

What is PLA? PLA Filament Explained

ABS (Acrylonitrile Butadiene Styrene)

ABS is known for its toughness and impact resistance. It is commonly used for functional parts, automotive components, and durable prototypes. However, ABS requires a heated bed and a well-ventilated area due to its tendency to emit fumes during printing.

Pros:

- Strong and impact-resistant

- Can withstand higher temperatures

Cons:

- Prone to warping without a heated bed

- Emits fumes while printing

Material Science – “ABS” Acrylonitrile Butadiene Styrene

PETG (Polyethylene Terephthalate Glycol)

PETG combines the ease of PLA with the durability of ABS. It is strong, flexible, and resistant to moisture and chemicals, making it a great choice for functional parts, food-safe containers, and outdoor applications.

Pros:

- Strong and flexible

- Minimal warping

- Water-resistant

Cons:

- Requires precise temperature control

- Can be stringy if not dialed in properly

Everything you need to know about PETG Filament for 3D printing!

TPU (Thermoplastic Polyurethane)

TPU is a flexible and rubber-like filament used for producing parts that need elasticity, such as phone cases, shoe soles, and gaskets. It requires a direct-drive extruder for optimal performance.

Pros:

- Flexible and impact-resistant

- Ideal for wearables and shock-absorbing parts

Cons:

- Requires slow printing speeds

- Not suitable for all printers

3d Printing TPU For Beginners!

Top Filament Recommendations

Overture’s PLA filament is a favorite among many 3D printing enthusiasts. It boasts over 20,000 reviews with a 4.5-star rating, reflecting its consistent quality and performance. Users appreciate its dimensional accuracy of ±0.03 mm and the use of recyclable cardboard spools. However, if you’re using a Bambu Lab AMS, be aware that the cardboard spools might present compatibility issues.

Key Features:

- Dimensional accuracy of ±0.03 mm

- Recyclable cardboard spool

- Wide range of colors available

Polymaker offers the PolyTerra PLA, known for its matte finish and eco-friendly approach. Priced around $20 per spool, it provides a wide selection of colors and textures. The filament comes on cardboard spools, which generally work well with most 3D printers, including the Bambu Lab AMS, as long as the spool is undamaged and spins freely.

Key Features:

- Matte finish for a unique look

- Eco-friendly packaging

- Extensive color and texture options

ELEGOO’s PLA filament is praised for its affordability and quality. With over 2,300 reviews and a 4.4-star rating, it offers a dimensional accuracy of ±0.02mm. A notable advantage is the price point—approximately $22 for two rolls of black PLA. The filament is wound on cardboard spools with a smooth finish, enhancing compatibility with various 3D printers.

Key Features:

- Dimensional accuracy of ±0.02mm

- Cost-effective pricing

- Smooth cardboard spools for better compatibility

SUNLU PLA is a widely used filament with over 16,500 reviews and a 4.4-star rating. It offers a dimensional accuracy of ±0.02mm and comes on plastic spools. While it has a good color selection and is often in stock, some users have reported occasional inconsistencies between batches. Despite this, many find it to be a reliable choice for various projects.

Key Features:

- Dimensional accuracy of ±0.02mm

- Available in various colors

- Comes on plastic spools

eSUN’s PLA+ filament is recognized for its enhanced toughness compared to standard PLA. It has garnered positive feedback for its performance and reliability. Users appreciate its high-speed printing capabilities and the quality of the finished prints.

Key Features:

- Enhanced toughness

- Suitable for high-speed printing

- Consistent performance

The 3D Filament Tier List! Which Should YOU Use?

Conclusion

Selecting the right 3D printer filament is an essential step in ensuring high-quality prints that match your needs. Whether you are a beginner looking for easy-to-use PLA, a hobbyist experimenting with different materials, or a professional needing high-performance filaments, Amazon offers a wide range of options to choose from.

By considering factors like durability, flexibility, and ease of use, you can find the best filament for your project. The recommendations provided here highlight some of the top-rated filaments, making your decision-making process easier. Be sure to read user reviews, check for compatibility with your printer, and test different brands to find what works best for you.

Happy Printing!